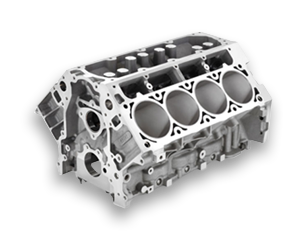

Reman 94-99 Non Turbo GMC 6.5 Diesel Long Block Engine

- Item #:

- PR-293051028599

- Ships From:

- Paterson, New Jersey, US

-

Powered by

Price:

Price: - $3,849.00

Our site may earn a commission when you click on links to various merchants and make a purchase.

Manufacturer: Promar Engine

Fitment Type: Direct Replacement

So don't buy another engine because it's a little cheaper in price, buy an engine from our company who has over 35 years of experience and is committed to the highest quality products and services offered in the industry.

This engine is remanufactured with the highest quality parts available including new camshaft, lifters, rocker arms, pushrods, oil pump with screen, pistons, piston rings, connecting rod bearings, main bearings, cam bearings, timing chain and timing gears, new cylinder heads and gaskets. Also shipping and core pickup is FREE in the United States with the exception of Alaska, Hawaii, all off-shore U.S. territories and possessions. No core deposit is required but the appropriate, rebuildable core must be returned. By purchasing this engine you agree to have the appropriate core ready for pickup or paid for in full within 30 days. After 30 days your warranty will be voided and you will be charged market value for your core.

REQUIRED INFORMATION

**We can not complete your order without all required information. After you make a purchase please provide as much of the following information as possible to insure you get the right engine for the year you have.

Vehicle Information

Year, Make, Model and Vin Number

Billing Information

Contact Person

Company Name

Billing Address

Phone Number

If shipping address is different please provide the following information.

Shipping Information

Contact Person

Company Name

Shipping Address

Phone Number

Shipping Option

Please let us know what shipping option you would like to use.

The first option is delivery to a business with a forklift readily available.

The second option is delivery of the engine to a business with a loading dock.

The third option is to pick up the engine at a UPS Freight shipping depot.

To find a UPS Freight shipping depot near you please go to the following link. https://www.upsfreight.com/ltl/apps/ServiceCenterDirectory

Delivery of the engine by truck equipped with a lift gate is $75 each way and residential delivery is an additional $50 each way.

Once engine ships tracking information will be sent to your email address.

To qualify for free shipping the business address must be a commercial property not residential. If you have any questions or concerns about shipping options please feel free to contact us.

SHIPPING AND HANDLING

Shipping is FREE each way to a commercial property or UPS Freight shipping depot in the United States with the exception of Alaska, Hawaii, all off-shore U.S. territories and possessions. If you require lift gate delivery or residential delivery those services are not free.

International customers we offer shipping to your closest major airport please contact us for details.

There are 3 shipping options to choose from which are free.

The first option is delivery to a business with a forklift readily available.

The second option is delivery of the engine to a business with a loading dock.

The third option is to pick up the engine at a UPS Freight shipping depot.

To find a UPS Freight shipping depot near you please go to the following link. https://www.upsfreight.com/ltl/apps/ServiceCenterDirectory

Delivery of the engine by truck equipped with a lift gate is $75 each way and residential delivery is an additional $50 each way.

Once engine ships tracking information will be sent to your email address.

To qualify for free shipping the business address must be a commercial property not residential. If you have any questions or concerns about shipping options please feel free to contact us.

CORE RETURN POLICY

All engines are sold on an exchange basis. While there is no core deposit required, all cores must be returned.

By purchasing our product you agree to have the appropriate, rebuildable core ready for pickup or paid for in full within 30 days. After 30 days your warranty will be voided and you will be charged market value for your core. Please call for immediate pickup.

If you do not have a core at all you can pay the core charge to maintain your warranty.

Core must be returned on a wooden pallet with a cardboard box over top. It's recommended you use the same pallet and cardboard box you received with the new engine. You will also receive a prepaid return shipping label with the new engine for the core. When the core is ready just attach the return shipping label then call the 800 number on the label to request pickup.

REMANUFACTURING PROCESS

Below are the 14 steps we use in our engine block remanufacturing process. To view our cylinder head and crankshaft process click the PROCESS link on the navigation menu above.

STEP 1) ENGINE BLOCK DISASSEMBLY

All blocks are visually inspected for casting defects prior to their disassembly and the beginning of engine block remanufacturing. The parts are then removed and individually inspected for damage and cause of failure. The oil and water passage plugs are removed to insure optimum results during the thermal cleaning process.

Only premium castings are used for our marine blocks, all castings are replaced in all salt-water applications. Our high performance engines are built with premium cores. In many applications new castings are used, as we never employ repaired castings or sleeved blocks. To retain your classic car's original block casting, Promar employs the artistry of our skilled casting repair technicians.

Dirty Engine Block

STEP 2) ENGINE BLOCK THERMAL CLEANING

The thermal cleaning system gives our customers the closest thing to a new casting, taking engine parts to a whole new level of clean. The heaters emit uniformly controlled heat, which is evenly distributed throughout the chamber. This method totally eliminates the concentration of intense heat or flame entering the chamber, which could overheat, warp or melt parts. The load is heated to 650-800 F (340-427C) in an oxygen deficient atmosphere, where the combustible hydrocarbons decompose and parts leave the oven completely dry. This baking process used on cast iron blocks only employs the Ace RKE 230 oven. Ash residue is easily removed by stainless steel shot blasting which is the next step of our engine restoration services.

Oven-Cleaned Engine Block

STEP 3) ENGINE BLOCK SHOT BLASTING

Our shot-blasting machine employs a cleaning method using stainless steel shot. This finishing process is used by Promar to remove surface contamination such as rust and irregularities from engine blocks during remanufacturing. The result of this method is a cleaner smoother surface finish to make easy the detection of surface and subsurface casting defects during quality inspection.

To insure stress free casting, the peening process is used to impart compression strength to metal parts. This is accomplished by metal shot pellets acting like miniature ball peen hammers as they strike the entire surface of the block. All iron castings are put through this process before a preliminary inspection for defects is done. This process using the AR HB41 is employed for cast iron blocks only and facilitates a more accurate magnetic particle inspection.

Engine Block After Shot Blasting

STEP 4) ENGINE BLOCK MAGNAFLUXING

Magnetic particle inspection is the most definitive method of detecting cracks and imperfections in any ferrous engine parts. This procedure, as part of our engine restoration services, assures the highest quality cast iron blocks. The next process is pressure testing, but first, let us explain how aluminum blocks are cleaned, pressure tested and checked for casting defects.

Engine Block Crack Detection

STEP 5) ENGINE BLOCK HIGH PRESSURE WASH

The first stop for a qualified aluminum engine block during remanufacturing is our AXE SW20 OS spray cleaning system. With twice the spraying power and a dramatically increased number of multi integrated spray nozzles, this state of the art system assures Promar that all oil, dirt and foreign material is removed from even the smallest of oiling holes. Cleanliness of the aluminum engine block is essential to insure an accurate inspection. This process is used on all aluminum engine blocks as a first step prior to the second step of ultrasonic cleaning.

AXE SW20 OS Spray Cleaning System

STEP 6) ENGINE BLOCK SONIC CLEANING

Promar's second process in the cleaning of aluminum blocks is the ultrasonic cleaning method, long known as the "benchmark" in cleaning and engine restoration services. Hundreds of specifications reference an ultrasonically cleaned part as the ultimate target for cleanliness. Ultrasonic cavitation is able to clean right down to the surface of a part and beyond. It is also able to reach internal areas, which are not accessible by using other cleaning means including spray and mechanical agitation. The forceful nature of ultrasonic energy provides the physical "push" required to break the mechanical and ionic bonds that hold very small particles to surfaces. Once cleaned the block is sent for pressure testing.

GMC 1818B Ultra Sonic Cleaner

STEP 7) ENGINE BLOCK PRESSURE TESTING

Promar uses the Delta Pressure tester to double check for pin holes after magnafluxing and dye testing are completed. Cracks and defects not detected during the first process are found at this time. This second process insures the integrity of all castings used in Promar products.

Delta 6000 Pressure Tester Machine

STEP 8) ENGINE BLOCK PREPARATION

A complete visual inspection of the block is performed. Repairs will be made to minor casting defects, removal of broken bolts are performed as well as repair and tapping of threads. Gasket surface repairs are performed to minimize stock removal. The next step of engine block remanufacturing is align honing.

Engine Block Preparation

STEP 9) ENGINE BLOCK MACHINING

Promar engines continued its commitment to excellence when we purchased the RMC CNC V40 enclosed machining center. This machine is fully computerized and is equipped with a 24 pocket arm style automatic tool changer. The RMC V40 is a very fast, accurate and versatile machine for all of our engine block and general machining needs. This machine has a wireless probe that automatically identifies the block, levels the block, measures deck heights & cylinder bore sizes. This computerized probe takes all operator error out of the setup process.

Promar uses this machine to resurface the decks through the milling process, bore the cylinders, chamfer the top of the cylinders, as well as line boring blocks and cylinder heads with our 90 degree boring head. With position repeatability within .0001", there is no machine more accurate than ours. When milling a block it is essential to acquire proper Ra finish for each block. This machine is set up to automatically determine Ra finish based on the type of block, be it aluminum or cast iron, and by the type of gasket used for each specific application. When milling we utilize CBN (cubic boron nitride) cutters, which are second in hardness only to a diamond. The surface finish is then checked by using the Mitutoyo SJ-301. The Mitutoyo SJ-301 is utilized twice, once after resurfacing and again before final assembly Promar insures proper measurement of Ra by using the SJ-301.

RMC V40 CNC Machine

RMC Digital Probe

RMC 360° 4th Axis Rotary Table and Block Fixture

8200 CNC High Speed Machining Control

STEP 10) ENGINE BLOCK ROD RECONDITIONING

The ideal equipment for precision rod reconditioning and pin fitting is the Sunnen LBB-1600 Hone, which measures accuracy within .0001". This hone method is preferred all over the world for its ability to produce a round and straight honed bore equal to or better than the manufacturer's new rods.

All high performance engines are fitted with ARP high strength bolts and nuts prior to rod reconditioning. Once reconditioning of the rods is accomplished the next step of engine restoration is honing of the cylinders.

Sunnen LBB-1600

Connecting Rod Bore Checking Process

STEP 11) ENGINE BLOCK HONING

Promar steps out of the Stone Age and into the Diamond Era with the purchase of their new Rottler H85AXY CNC Honing Machine. Honing hundreds of blocks a month, Promar could not pass up the opportunity to buy the machine with the perfect combination of machine tooling and abrasives for precision automatic cylinder honing. Promar was using Sunnen’s CV616 honing machine where, at times, even an experienced operator could struggle to get desired results. The new SV-10 machine can not be matched when it comes to the roundness, straightness and finish quality of its Diamond Honed cylinders. The machine is equipped with a patented full-bore profile display which shows a real-time cross section of the bore, taking the guesswork out of removing taper. For unattended operation, the auto dwell feature will automatically dwell the honing action in the tightest areas of the bore. The machine also offers infinitely variable crosshatch angles for any bore diameter and cylinder length – all of which can be changed on the fly.

Promar insures proper measurement of Ra by utilizing the Mitutoyo SJ-301 twice, once after honing and again before final assembly. Final assembly and completion of engine block remanufacturing is not started until all blocks go through a final wash.

Rottler H85AXY CNC Honing Machine

Engine Block Honing Process

STEP 12) ENGINE BLOCK HIGH PRESSURE WASH

Following these precise machining procedures and engine restoration services, our blocks undergo a second high pressure wash cycle to guarantee the removal of any debris that may have adhered or become dislodged during the machining process. Absolute cleanliness is necessary for the next step, which is final assembly. After the blocks receive a final wash we clean all parts ultrasonically.

AXE SW 20-OS

STEP 13) ENGINE BLOCK SONIC CLEANING

Promar's second process is ultra sonic cleaning of all parts old and new prior to assembly of the engine. This Ultrasonic Cleaning Method is long known as the "benchmark" in cleaning. Hundreds of specifications reference an ultrasonically cleaned part as the ultimate target for cleanliness. Ultrasonic cavitation is able to clean right down to the surface of a part and beyond. It is also able to reach internal areas, which are not accessible by using other cleaning means including spray and mechanical agitation. The forceful nature of ultrasonic energy provides the physical "push" required to break the mechanical and ionic bonds that hold very small particles to surfaces. Once the parts are cleaned, they are now ready to be assembled in our Promar engine.

GMC-1818B Ultra Sonic Cleaner

STEP 14) ENGINE BLOCK ASSEMBLY

At Promar there are no assembly lines during engine block remanufacturing. All engines are custom built. Each assembler does a visual inspection of the block, heads, crankshaft and all-inclusive parts prior to assembly. The Ra tester is used to check all cylinder bores, crankshaft journals and gasket surfaces. All parts such as crankshafts, bearings, cylinder bores, pistons, rings, connection rods, main saddles, lifter and camshaft bores are miced for proper size.

Each block is fitted with new full circle cam bearings, oil restrictors, relief valves, new water and oil plugs. The crankshaft is fitted in the block with new high quality bearings and each journal clearance is checked with plastigage, torqued and double-checked. New rings are then fitted in each bore to assure proper end gap. Each new piston is checked for proper clearance in each bore. The rings are installed on the piston and assembled into the bores. Each assembly is supplied with new high quality bearings and each journal clearance is checked with plastigage, torqued and double-checked. A new camshaft is then fitted into cam bearings bores and all new timing components are installed and double-checked by an assembly manager.

Cylinder heads are then installed with new head bolts and new Felpro or Victor head gaskets. The block now receives new lifters, push rods and rocker arms which are adjusted and a second check completed by an assembly manager. Each cylinder is then accurately checked for seal integrity to assure no compression or water leaks. At this point the engine is primed with special lubricant and a new oil pump. The residual parts of the gasket set are sent along with the engine. The assembly manager then conducts the final inspection of the engine.

All engines come with an installation manual. Bulletins about your specific engine are also enclosed in the packaging. Promar engines are secured onto a wooden pallet where vulnerable parts are protected from damage by corner covers. The entire block is wrapped in a durable plastic sheath to protect your engine from outside elements.

Engine Block Check

Engine Block with Crankshaft Installed

Engine Block with Cylinder Head Installed

Completed & Wrapped Engine Block

**We can not complete your order without all required information. After you make a purchase please provide as much of the following information as possible to insure you get the right engine for the year you have.

Vehicle Information

Year, Make, Model and Vin Number

Billing Information

Contact Person

Company Name

Billing Address

Phone Number

If shipping address is different please provide the following information.

Shipping Information

Contact Person

Company Name

Shipping Address

Phone Number

Shipping Option

Please let us know what shipping option you would like to use.

The first option is delivery to a business with a forklift readily available.

The second option is delivery of the engine to a business with a loading dock.

The third option is to pick up the engine at a UPS Freight shipping depot.

To find a UPS Freight shipping depot near you please go to the following link. https://www.upsfreight.com/ltl/apps/ServiceCenterDirectory

Delivery of the engine by truck equipped with a lift gate is $75 each way and residential delivery is an additional $50 each way.

Once engine ships tracking information will be sent to your email address.

To qualify for free shipping the business address must be a commercial property not residential. If you have any questions or concerns about shipping options please feel free to contact us.

Shipping is FREE each way to a commercial property or UPS Freight shipping depot in the United States with the exception of Alaska, Hawaii, all off-shore U.S. territories and possessions. If you require lift gate delivery or residential delivery those services are not free.

International customers we offer shipping to your closest major airport please contact us for details.

There are 3 shipping options to choose from which are free.

The first option is delivery to a business with a forklift readily available.

The second option is delivery of the engine to a business with a loading dock.

The third option is to pick up the engine at a UPS Freight shipping depot.

To find a UPS Freight shipping depot near you please go to the following link. https://www.upsfreight.com/ltl/apps/ServiceCenterDirectory

Delivery of the engine by truck equipped with a lift gate is $75 each way and residential delivery is an additional $50 each way.

Once engine ships tracking information will be sent to your email address.

To qualify for free shipping the business address must be a commercial property not residential. If you have any questions or concerns about shipping options please feel free to contact us.

All engines are sold on an exchange basis. While there is no core deposit required, all cores must be returned.

By purchasing our product you agree to have the appropriate, rebuildable core ready for pickup or paid for in full within 30 days. After 30 days your warranty will be voided and you will be charged market value for your core. Please call for immediate pickup.

If you do not have a core at all you can pay the core charge to maintain your warranty.

Core must be returned on a wooden pallet with a cardboard box over top. It's recommended you use the same pallet and cardboard box you received with the new engine. You will also receive a prepaid return shipping label with the new engine for the core. When the core is ready just attach the return shipping label then call the 800 number on the label to request pickup.

REMANUFACTURING PROCESS

ENGINE BLOCKS

Engine block remanufacturing process

VIEW PROCESS

CYLINDER HEADS

Cylinder head remanufacturing process

VIEW PROCESS

CRANKSHAFTS

Crankshaft remanufacturing process

VIEW PROCESS

ENGINE BLOCK REMANUFACTURING

Below are the 14 steps we use in our engine block remanufacturing process.

STEP 1) ENGINE BLOCK DISASSEMBLY

All blocks are visually inspected for casting defects prior to their disassembly and the beginning of engine block remanufacturing. The parts are then removed and individually inspected for damage and cause of failure. The oil and water passage plugs are removed to insure optimum results during the thermal cleaning process.

Only premium castings are used for our marine blocks, all castings are replaced in all salt-water applications. Our high performance engines are built with premium cores. In many applications new castings are used, as we never employ repaired castings or sleeved blocks. To retain your classic car's original block casting, Promar employs the artistry of our skilled casting repair technicians.

Dirty Engine Block

STEP 2) ENGINE BLOCK THERMAL CLEANING

The thermal cleaning system gives our customers the closest thing to a new casting, taking engine parts to a whole new level of clean. The heaters emit uniformly controlled heat, which is evenly distributed throughout the chamber. This method totally eliminates the concentration of intense heat or flame entering the chamber, which could overheat, warp or melt parts. The load is heated to 650-800 F (340-427C) in an oxygen deficient atmosphere, where the combustible hydrocarbons decompose and parts leave the oven completely dry. This baking process used on cast iron blocks only employs the Ace RKE 230 oven. Ash residue is easily removed by stainless steel shot blasting which is the next step of our engine restoration services.

Oven-Cleaned Engine Block

STEP 3) ENGINE BLOCK SHOT BLASTING

Our shot-blasting machine employs a cleaning method using stainless steel shot. This finishing process is used by Promar to remove surface contamination such as rust and irregularities from engine blocks during remanufacturing. The result of this method is a cleaner smoother surface finish to make easy the detection of surface and subsurface casting defects during quality inspection.

To insure stress free casting, the peening process is used to impart compression strength to metal parts. This is accomplished by metal shot pellets acting like miniature ball peen hammers as they strike the entire surface of the block. All iron castings are put through this process before a preliminary inspection for defects is done. This process using the AR HB41 is employed for cast iron blocks only and facilitates a more accurate magnetic particle inspection.

Engine Block After Shot Blasting

STEP 4) ENGINE BLOCK MAGNAFLUXING

Magnetic particle inspection is the most definitive method of detecting cracks and imperfections in any ferrous engine parts. This procedure, as part of our engine restoration services, assures the highest quality cast iron blocks. The next process is pressure testing, but first, let us explain how aluminum blocks are cleaned, pressure tested and checked for casting defects.

Engine Block Crack Detection

STEP 5) ENGINE BLOCK HIGH PRESSURE WASH

The first stop for a qualified aluminum engine block during remanufacturing is our AXE SW20 OS spray cleaning system. With twice the spraying power and a dramatically increased number of multi integrated spray nozzles, this state of the art system assures Promar that all oil, dirt and foreign material is removed from even the smallest of oiling holes. Cleanliness of the aluminum engine block is essential to insure an accurate inspection. This process is used on all aluminum engine blocks as a first step prior to the second step of ultrasonic cleaning.

AXE SW20 OS Spray Cleaning System

STEP 6) ENGINE BLOCK SONIC CLEANING

Promar's second process in the cleaning of aluminum blocks is the ultrasonic cleaning method, long known as the "benchmark" in cleaning and engine restoration services. Hundreds of specifications reference an ultrasonically cleaned part as the ultimate target for cleanliness. Ultrasonic cavitation is able to clean right down to the surface of a part and beyond. It is also able to reach internal areas, which are not accessible by using other cleaning means including spray and mechanical agitation. The forceful nature of ultrasonic energy provides the physical "push" required to break the mechanical and ionic bonds that hold very small particles to surfaces. Once cleaned the block is sent for pressure testing.

GMC 1818B Ultra Sonic Cleaner

STEP 7) ENGINE BLOCK PRESSURE TESTING

Promar uses the Delta Pressure tester to double check for pin holes after magnafluxing and dye testing are completed. Cracks and defects not detected during the first process are found at this time. This second process insures the integrity of all castings used in Promar products.

Delta 6000 Pressure Tester Machine

STEP 8) ENGINE BLOCK PREPARATION

A complete visual inspection of the block is performed. Repairs will be made to minor casting defects, removal of broken bolts are performed as well as repair and tapping of threads. Gasket surface repairs are performed to minimize stock removal. The next step of engine block remanufacturing is align honing.

Engine Block Preparation

STEP 9) ENGINE BLOCK MACHINING

Promar engines continued its commitment to excellence when we purchased the RMC CNC V40 enclosed machining center. This machine is fully computerized and is equipped with a 24 pocket arm style automatic tool changer. The RMC V40 is a very fast, accurate and versatile machine for all of our engine block and general machining needs. This machine has a wireless probe that automatically identifies the block, levels the block, measures deck heights & cylinder bore sizes. This computerized probe takes all operator error out of the setup process.

Promar uses this machine to resurface the decks through the milling process, bore the cylinders, chamfer the top of the cylinders, as well as line boring blocks and cylinder heads with our 90 degree boring head. With position repeatability within .0001", there is no machine more accurate than ours. When milling a block it is essential to acquire proper Ra finish for each block. This machine is set up to automatically determine Ra finish based on the type of block, be it aluminum or cast iron, and by the type of gasket used for each specific application. When milling we utilize CBN (cubic boron nitride) cutters, which are second in hardness only to a diamond. The surface finish is then checked by using the Mitutoyo SJ-301. The Mitutoyo SJ-301 is utilized twice, once after resurfacing and again before final assembly Promar insures proper measurement of Ra by using the SJ-301.

RMC V40 CNC Machine

RMC Digital Probe

RMC 360° 4th Axis Rotary Table and Block Fixture

8200 CNC High Speed Machining Control

STEP 10) ENGINE BLOCK ROD RECONDITIONING

The ideal equipment for precision rod reconditioning and pin fitting is the Sunnen LBB-1600 Hone, which measures accuracy within .0001". This hone method is preferred all over the world for its ability to produce a round and straight honed bore equal to or better than the manufacturer's new rods.

All high performance engines are fitted with ARP high strength bolts and nuts prior to rod reconditioning. Once reconditioning of the rods is accomplished the next step of engine restoration is honing of the cylinders.

Sunnen LBB-1600

Connecting Rod Bore Checking Process

STEP 11) ENGINE BLOCK HONING

Promar steps out of the Stone Age and into the Diamond Era with the purchase of their new Rottler H85AXY CNC Honing Machine. Honing hundreds of blocks a month, Promar could not pass up the opportunity to buy the machine with the perfect combination of machine tooling and abrasives for precision automatic cylinder honing. Promar was using Sunnen’s CV616 honing machine where, at times, even an experienced operator could struggle to get desired results. The new SV-10 machine can not be matched when it comes to the roundness, straightness and finish quality of its Diamond Honed cylinders. The machine is equipped with a patented full-bore profile display which shows a real-time cross section of the bore, taking the guesswork out of removing taper. For unattended operation, the auto dwell feature will automatically dwell the honing action in the tightest areas of the bore. The machine also offers infinitely variable crosshatch angles for any bore diameter and cylinder length – all of which can be changed on the fly.

Promar insures proper measurement of Ra by utilizing the Mitutoyo SJ-301 twice, once after honing and again before final assembly. Final assembly and completion of engine block remanufacturing is not started until all blocks go through a final wash.

Rottler H85AXY CNC Honing Machine

Engine Block Honing Process

STEP 12) ENGINE BLOCK HIGH PRESSURE WASH

Following these precise machining procedures and engine restoration services, our blocks undergo a second high pressure wash cycle to guarantee the removal of any debris that may have adhered or become dislodged during the machining process. Absolute cleanliness is necessary for the next step, which is final assembly. After the blocks receive a final wash we clean all parts ultrasonically.

AXE SW 20-OS

STEP 13) ENGINE BLOCK SONIC CLEANING

Promar's second process is ultra sonic cleaning of all parts old and new prior to assembly of the engine. This Ultrasonic Cleaning Method is long known as the "benchmark" in cleaning. Hundreds of specifications reference an ultrasonically cleaned part as the ultimate target for cleanliness. Ultrasonic cavitation is able to clean right down to the surface of a part and beyond. It is also able to reach internal areas, which are not accessible by using other cleaning means including spray and mechanical agitation. The forceful nature of ultrasonic energy provides the physical "push" required to break the mechanical and ionic bonds that hold very small particles to surfaces. Once the parts are cleaned, they are now ready to be assembled in our Promar engine.

GMC-1818B Ultra Sonic Cleaner

STEP 14) ENGINE BLOCK ASSEMBLY

At Promar there are no assembly lines during engine block remanufacturing. All engines are custom built. Each assembler does a visual inspection of the block, heads, crankshaft and all-inclusive parts prior to assembly. The Ra tester is used to check all cylinder bores, crankshaft journals and gasket surfaces. All parts such as crankshafts, bearings, cylinder bores, pistons, rings, connection rods, main saddles, lifter and camshaft bores are miced for proper size.

Each block is fitted with new full circle cam bearings, oil restrictors, relief valves, new water and oil plugs. The crankshaft is fitted in the block with new high quality bearings and each journal clearance is checked with plastigage, torqued and double-checked. New rings are then fitted in each bore to assure proper end gap. Each new piston is checked for proper clearance in each bore. The rings are installed on the piston and assembled into the bores. Each assembly is supplied with new high quality bearings and each journal clearance is checked with plastigage, torqued and double-checked. A new camshaft is then fitted into cam bearings bores and all new timing components are installed and double-checked by an assembly manager.

Cylinder heads are then installed with new head bolts and new Felpro or Victor head gaskets. The block now receives new lifters, push rods and rocker arms which are adjusted and a second check completed by an assembly manager. Each cylinder is then accurately checked for seal integrity to assure no compression or water leaks. At this point the engine is primed with special lubricant and a new oil pump. The residual parts of the gasket set are sent along with the engine. The assembly manager then conducts the final inspection of the engine.

All engines come with an installation manual. Bulletins about your specific engine are also enclosed in the packaging. Promar engines are secured onto a wooden pallet where vulnerable parts are protected from damage by corner covers. The entire block is wrapped in a durable plastic sheath to protect your engine from outside elements.

Engine Block Check

Engine Block with Crankshaft Installed

Engine Block with Cylinder Head Installed

Completed & Wrapped Engine Block

CYLINDER HEAD REMANUFACTURING

Below are the 14 steps we use in our cylinder head remanufacturing process.

STEP 1) CYLINDER HEAD DISASSEMBLY

All cylinder heads are visually inspected for casting defects prior to their disassembly. The parts are then removed and individually inspected for damage and cause of failure. The oil and water passage plugs are removed to insure optimum results during the thermal cleaning process.

Only premium castings are used for our marine cylinder heads, all castings are replaced for all the salt-water applications. Our high performance cylinder heads are built with premium cores. In many applications new castings are used, as we never employ repaired castings. To retain your classic cars's original cylinder head casting, Promar employs the best skilled casting repair technicians in the industry.

Dirty Cylinder Head

STEP 2) CYLINDER HEAD THERMAL CLEANING

The thermal cleaning system gives our customers the closest thing to a new casting, taking engine parts to a whole new level of clean. The heaters emit uniformly controlled heat, which is evenly distributed throughout the chamber. This method totally eliminates the concentration of intense heat or flame entering the chamber, which could overheat, warp or melt parts. The load is heated to 650-800 F (340-427C) in an oxygen deficient atmosphere, where the combustible hydrocarbons decompose and parts leave the oven completely dry. This baking process used on cast iron cylinder heads only employs the Ace RKE 230 oven. Ash residue is easily removed by stainless steel shot blasting which is the next step in the cylinder head repair process.

Oven-Cleaned Cylinder Head

STEP 3) CYLINDER HEAD SHOT BLASTING

Our shot-blasting machine employs a cleaning method using stainless steel shot. This finishing process is used by Promar to remove surface contamination such as rust and irregularities from cylinder heads during remanufacturing. The result of this method is a cleaner smoother surface finish to make easy the detection of surface and subsurface casting defects during quality inspection.

To insure stress free casting, the peening process is used to impart compression strength to metal parts. This is accomplished by metal shot pellets acting like miniature ball peen hammers as they strike the entire surface of the cylinder head. All iron castings are put through this process before a preliminary inspection for defects is done. This process using the AR-HB41 is employed for cast iron cylinder heads only and facilitates a more accurate magnetic particle inspection.

Shot-Blasted Cylinder Head

STEP 4) CYLINDER HEAD MAGNAFLUXING

Magnetic particle inspection is the most definitive method of detecting cracks and imperfections in any ferrous engine parts. This procedure assures the highest quality cast iron cylinder heads. The next process of cylinder head repair is pressure testing, but first, let us explain how aluminum cylinder heads are cleaned, pressure tested and checked for casting defects.

Magnetic Particle Inspection Process

STEP 5) CYLINDER HEAD HIGH PRESSURE WASH

The first stop for a qualified aluminum cylinder head during remanufacturing is our AXE SW20 OS spray cleaning system. With twice the spraying power and a dramatically increased number of multi integrated spray nozzles, this state of the art system assures Promar that all oil, dirt and foreign material is removed from even the smallest of oiling holes. Cleanliness of the aluminum cylinder head is essential to insure an accurate inspection. This process is used on all aluminum cylinder heads as a first step prior to the second step of ultrasonic cleaning.

AXE SW-20 OS Spray Cleaning Machine

STEP 6) CYLINDER HEAD SONIC CLEANING

Promar's second process in the cleaning of aluminum cylinder heads during repair is the ultrasonic cleaning method, long known as the "benchmark" in cleaning. Hundreds of specifications reference an ultrasonically cleaned part as the ultimate target for cleanliness. Ultrasonic cavitation is able to clean right down to the surface of a part and beyond. It is also able to reach internal areas, which are not accessible by using other cleaning means including spray and mechanical agitation. The forceful nature of ultrasonic energy provides the physical "push" required to break the mechanical and ionic bonds that hold very small particles to surfaces. Once cleaned the cylinder head is sent for pressure testing.

GMC-1818B Ultra Sonic Cleaner

STEP 7) CYLINDER HEAD PRESSURE TESTING

Promar uses the Delta Pressure tester to double check for pin holes after magnafluxing and dye testing are completed. Cracks and defects not detected during the first cylinder head remanufacturing process are found at this time. This second process insures the integrity of all castings used in Promar products.

Delta 6000 Pressure Tester

Pressure Testing Process

STEP 8) CYLINDER HEAD PREPARATION

During the head preparation and after pressure testing, minor cylinder head repairs are carried out. Broken bolts are removed and repair and tapping of threads completed. Gasket surface repairs are accomplished in order to minimize stock removal. All guides are inspected for replacement or fitted with new oversized valves. The heads are now ready for line honing.

Broken Bolt Removal Process

STEP 9) CYLINDER HEAD LINE HONE

Promar engines continued its commitment to excellence when we purchased the RMC CNC V40 enclosed machining center. This machine is fully computerized and is equipped with a 24 pocket arm style automatic tool changer. The RMC V40 is a very fast, accurate and versatile machine for all of our engine block and general machining needs. Promar uses this to line bore cylinder heads from engines with overhead camshaft designs. With position repeatability within .0001”, there is no cylinder head machine more accurate than ours. After bored, all camshaft bores are measured with our Sunnen GR-6241 dial bore gauge to ensure sizes are within .0001".

RMC V40 CNC Machine

RMC Line Hone

STEP10) CYLINDER HEAD MACHINING

In cylinder head machinging, classic car heads previously designed to use leaded gas must be updated with seats and valves compatible for use with unleaded gas. Marine and high performance heads are fitted with new guides before valve seat resurfacing.

STEP 11) CYLINDER HEAD SEAT REFACING

Promar's head machining center has a rigid head and base enabling delivery of high precision multiple angle seat to guide concentricity within .001 or less per 1" of valve diameter. The variable speed cutter head on the DMC series 2000 assures chatter free seat finish. All seats are checked with a vacuum tester while still on the machine. A second check is done after final assembly to insure optimum valve and seat seal. The next process during cylinder head repair is milling of the heads.

HCM-2000

Valve Seat Resurfacing

STEP 12) CYLINDER HEAD MILLING

Milling machines that are used by Promar are set up specifically for heads. The Winona Van Norman M3000 machines are used for their variable feed rate, which is essential to acquire proper Ra finish for each head. Ra finish determination is based on the type of head, be it aluminum or cast iron and by the type of gasket used for each specific application. These machines utilize CBN (cubic boron nitride) cutters, which are second in hardness only to a diamond, to maximize quality work during cylinder head remanufacturing. During the cutting process heat from friction is absorbed and carried off by the discarded metal chips thus resulting in improved accuracy and excellent surface finish. Promar insures proper measurement of Ra by utilizing the Mitutoyo SJ-301 twice, once after resurfacing and again before final assembly.

M-3000

Surface Ra Testing

STEP 13) CYLINDER HEAD FINAL WASH

All heads are then washed with a mild detergent and rinsed before the final assembly.

Cylinder Head Washing Process

STEP 14) CYLINDER HEAD ASSEMBLY

At the time of assembly, Promar installs new oil and water plugs in all its cylinder heads, using brass plugs in our marine applications. The springs are checked for proper pressure as well as the installed heights checked and new Viton seals installed. All our overhead cam heads include new cams, rockers, lifters and cam seals.

The final assembly process is accomplished using the CHW-50 Cylinder Head Workstation. This machine takes the work out of head assembly and disassembly. It makes precision automotive head rebuilding easier than ever. The entire valve train, including cams, rocker arms, cam buckets, springs, valves, etc. can be easily removed, reinstalled and adjusted while the head is mounted in the workstation. Once final assembly is completed the heads are vacuum tested and then wrapped.

CHW-50 Cylinder Head Workstation

Head Spring

CRANKSHAFT REMANUFACTURING

Below are the 8 steps we use in our crankshaft remanufacturing process.

STEP 1) CRANKSHAFT DISASSEMBLY

Crankshafts are removed from the engine blocks so a visual inspection of the crank casting can be done. Crankshafts with bad keyways, journals spun beyond machining specs or worn thrusts surfaces will be discarded. Adhering to strict quality standards, Promar will never use a welded shaft. Once qualified in preliminary inspection, the crank is then sent for initial cleaning.

Dirty Crankshaft

STEP 2) CRANKSHAFT HIGH-PRESSURE WASH

The first stop for a qualified crankshaft during our crankshaft repair process is our AXE SW20 OS spray cleaning system. With twice the spraying power and dramatically increased number of multi-integrated spray nozzles, the state of the art system assures Promar that all oil, dirt and foreign material is removed from even the smallest of oiling holes. The cleanliness of this crank is essential to insure an accurate magnetic particle crack detection test.

Crankshaft After Washing Process

AXE SE20 OS Spray Cleaning System

STEP 3) CRANKSHAFT MAGNETIC PARTICLE INSPECTION

Magnetic particle inspection is the most definitive methods of detecting cracks and imperfections in any ferrous engine parts. This procedure assures the highest quality cores for crankshaft remanufacturing.

DCM-2400 Magnetic Particle Inspection

STEP 4) CRANKSHAFT GRINDING

Continuing our efforts to produce the best and most reliable crankshaft repair product in the industry, we utilize the Berco RTM 225A precision crankshaft grinder. Coupled with our expert craftsmen, this state of the art unit incorporates rigid construction and precise controls; affording Promar customers the most accurately ground crankshafts possible. Precise controls afford precision grinding, which is followed up by brush cleaning and chamfering of all oil passages.

Berco RTM-225A Precision Crankshaft Grinder

Crankshaft Grinding Process

STEP 5) CRANKSHAFT HIGH PRESSURE WASH

Following these precise machining procedures, our cranks undergo a second high pressure wash cycle to guarantee the removal of any debris that may have adhered or become dislodged during the grinding process. Absolute cleanliness is necessary for the next step of crankshaft remanufacturing, which is micro-polishing and or balancing if needed.

AXE SW20 OS Spray Cleaning System

Crankshaft After Washing Process

STEP 6) CRANKSHAFT BALANCING

Promar's digitally controlled balancer is extremely accurate, producing precise balanced crankshafts during repair, it has the ability to measure unbalance from .01 to 1,000 grams on work pieces weighing up to 500 lbs. (226kg). This process using the Sunnen DCB 2000 is optional for this application.

Sunnen DCB-2000

Crankshaft Balancing Process

STEP 7) CRANKSHAFT MICROPOLISHING

Promar uses a crankshaft micro polisher with a rigid polishing system during remanufacturing. The QPAC Q190-38-3 has a solid abrasive tape that wraps around the journal and is backed up with a shoe. This shoe applies equal pressure all the way around the journal while it is being polished.

Traditional polishing techniques use a manually operated belt sander that can alter the geometry of the journal, slightly creating some taper or out-of-roundness. If the surface finish on the crankshaft journal is not right or the geometry is slightly off, the bearings will suffer the consequences when the crankshaft is put into service. While polishing in one direction and then automatically polishing in the opposite direction, the QPAC system leaves a better finish and eliminates microscopic peaks that can cause premature bearing failure. The finishing process always ends in the same direction as the engine rotation.

For thrust surfaces, a separate polishing arm is used. Polishing the thrust surface on the crank is important to minimize the risk of thrust failure on vehicles that have electronic torque converters.

With many of today's engines requiring extremely smooth journal finishes (as low as 6 Ra or less) because of tighter bearing clearances and the use of thinner viscosity 5W-30 motor oils, there is little margin for error. In one pass the QPAC takes the finish down to 6 Ra or less and provides a superior finish to any polishing systems out there today.

QPAC Crankshaft Micro-Polisher

Crankshaft Polishing Process

Crankshaft Ra Check

STEP 8) CRANKSHAFT FINAL WASH

Our spray cleaner system carries twice the horsepower and twice the amount of nozzles than most spray cabinets. This machine assures Promar that any dirt, metal or oils from crankshaft repair and remanufacturing are removed before final assembly. This is the third and final wash performed after the micro polishing.

Crankshaft Rinsing Process

Completed & Wrapped Crankshaft

Q: Is shipping and core pickup really free in the US?

A: Shipping is FREE each way to a commercial property or UPS Freight shipping depot in the United States with the exception of Alaska, Hawaii, all off-shore U.S. territories and possessions. If you require lift gate delivery or residential delivery those services are not free.

Q: Do you offer international shipping?

A: Yes we offer international shipping airport to airport. You will need to pickup the engine from your closest major airport. Please contact us for details.

Q: Does the core have to be returned the same time the new engine arrives?

A: You have up to 30 days to return your core. Core must be returned on a wooden pallet with a cardboard box over top. It's recommended you use the same pallet and cardboard box you received with the new engine. You will also receive a prepaid return shipping label with the new engine for the core. When the core is ready just attach the return shipping label then call the 800 number on the label to request pickup.

Q: Can you remanufacture my engine?

A: Yes we can pick up your engine, remanufacture it and ship it back to you. Shipping will be FREE each way to a commercial property or UPS Freight shipping depot in the United States with the exception of Alaska, Hawaii, all off-shore U.S. territories and possessions. If you require lift gate delivery or residential delivery those services are not free.

Q: What is the horse power and torque on this engine?

A: We remanufacture our engines back to factory so the horsepower will be the same as your original engine. We do not have a list of horsepower ratings that information should be in your owners manual.

Q: Can I get a short block version of this engine?

A: We offer short blocks for some engines but it only comes with a 6 month warranty and shipping is not free.

Q: What if I don’t have a core to return?

A: If you have no core or buy an engine that not the same as your current engine you will have to pay an upfront core charge.

Q: What if my core is cracked?

A: We do not accept engine cores with cracks you will have to pay an upfront core charge.

Q: Are your engines complete and ready to drop in?

A: No, You will receive the engine as a long block which is the heads, block and new internal components. You must reuse your external components like valve covers, timing cover, oil pan, manifolds, injectors, flywheel, ect… We do supply you with an oil pump and all the gasket to finish the installation.

Q: Do you dyno test your engines?

A: Dyno testing is available. Starting price is $800.

Q: What are your business hours?

A: Our business hours are 8am-5pm EST Monday-Friday.

Q: Can I pickup an engine from your company?

A: Yes, but you will have to pay an additional NJ sales tax on the engine.

Q: I want to put a different engine in my vehicle is that possible?

A: Yes in some cases, but modifications may be needed to accommodate the change.

ONLINE WARRANTY

I. Owner's and Installer's Responsibilities

STOP! Have you checked or replaced the following? Radiator, water pump, thermostat, belts, hoses, fan and coolant temperature sensors, exhaust system and catalytic converter, oil pump, oil cooler and lines, oil pump pick up screen, torque converter, transmission and related components, distributor and or related timing pick-ups, modules, oxygen sensors, fuel filters, EGR valves, fuel regulators, etc. This is not an unconditional warranty against all hazards and failures. The products distributed by Promar are warranted to the Original installing dealer and vehicle owner against defects in parts or factory workmanship. This is a non-transferable warranty unless Promar's Customer Service Department is notified in writing and the vehicle is in service for no longer than twelve months and the fee set forth below is paid with all transfer information properly completed. Non compliance to break-in procedures and Oil requirements will void the warranty. Promar does not assume responsibility on behalf of the installing dealer, their technicians, and parts transferred from original engine, or unauthorized repair work. Additional installer and owners obligations; after engine has been driven for 500 miles engine oil and filter must be changed. It is mandatory that all engine fluids be routinely changed, maintained and checked for proper levels as described within. It is also mandatory to change the oil and filter every 4,000 miles according to O.E.M. specifications. All costs of these services are the owner's obligations and should be documented with strict repair or maintenance records. Engine coolant must be maintained and checked for proper levels and protection. Coolant must be changed every 24 months or 30,000 miles or which ever comes first. Warranty will not cover rotted freeze plugs. Warranty information must be completed and mailed to Promar within 14 days after invoice date. Installing shop and owner of the vehicle must accurately fill out all warranty information and retain a copy of the warranty. All initial warranty notifications must be made through installing dealer. Failure to perform these conditions set forth herein voids the warranty. Warning! If you replace your old engine or cylinder head(s) and do not check the above items mentioned for cause of failure, chances are any replacement can fail again! Take time out to determine the actual cause of the failure to insure your customer trouble free operation of this replacement unit.

II. Limited Warranty

Remanufacturer warrants to their Distributor and Original Purchaser that their remanufactured Engine or Cylinder head(s) shall be free of defects from materials and or workmanship, when properly installed by a trained technician, and used for normal use and service for the periods of time or distance from original date of purchase or which ever occurs first. Subject to the following terms and conditions listed below. Note: Installing dealer must provide proof of purchase (warranty registration number) before any authorization of alleged warranty work is performed. Installing dealer must notify Promar to obtain work order authorization, NO EXCEPTIONS. No claims shall be honored if prior notification has not been obtained. Promar reserves the right to have any and all alleged warranty parts inspected prior to claims being honored. Money due under this warranty will be distributed after inspection has been made. Repairs or replacement will be made within a reasonable time, after receipt of goods deemed to be defective, enters our facility. Promar reserves the right to have any and or all parts inspected by their original manufacturer for warranty determination. Any parts discarded by installing dealer for warranty claims will not be honored for reimbursement.

Warranty does not cover and is void as a result of abnormal operating temperatures (this includes melted or missing heat tabs that are adhered to the engine or cylinder head to monitor the operating temperatures). In addition the following criteria will void the warranty: accident, racing, lack of proper lubrication, misuse, detonation/pre-ignition, broken connecting rods or pistons (or subsequent damage to block) on supercharged or turbocharged engines, improper or contaminated fuel, and or oil, thrust bearing wear due to transmission related components or problems, faulty/rotted freeze plugs due to lack of cooling system maintenance and or ground straps and vehicle modifications that can damage the engine. Detonation/pre-ignition damage includes but is not limited to melted or broken pistons, rings, damaged cylinder head(s) and their related parts. Causes include inoperative or malfunctioning computer and or emissions control and ignition devices, clogged catalyst or exhaust systems, etc. Modifications include but are not limited to superchargers, computer PROM changes, over sized tires or anything that will alter the performance of the vehicle from its O.E.M. status. Gaskets that are not supplied or installed by Promar are not covered by this warranty.

Warranty does not cover towing, vehicle rental, oil, oil filter, Freon, antifreeze, incidental, special consequential or exemplary damages resulting from loss of time, or use of the vehicle, or for any service not expressly provided herein, relating to or arising from products supplied by Promar. Repairs or replacements do not extend or renew length of warranty, nor does it apply fault. Water Pumps, Timing belts, timing idlers, Seals, Gaskets installed by Promar only receive a 12 month warranty. Promar does not cover camshaft lobe or lifter wear on flat lifters, proper break in procedures, and break in oil, must be followed.

III. Warranty Claims and Procedure

Any and all warranty claims: Are to be brought to the attention of the installing dealer not Promar. Promar will reimburse all authorized repairs at a flat rate schedule that is not to exceed Promar 's printed warranty in effect at time of original purchase using Chilton, Motor's or Alldata repair manual for guidelines. All warranty parts will be held at Promar 's facility for 30 days after inspection of parts have been made.

Hourly rates for all eligible authorized labor claims will be compensated at jobbers wholesale labor rates and not to exceed $45.00 per hour. Any additional labor claim or claims that are not covered herein will be the sole responsibility of the installer and owner of the vehicle. Maximum liability allowance shall not exceed $540.00 per engine replacement, or $150.00 per cylinder head(s) replacement. Invoices must accompany any and all claims; no claims will be honored if any outstanding money, engine or cylinder head(s) cores or invoices are due to Promar. Alleged warranty parts will be held for 30 days after receipt and then discarded. Any request for monetary compensation for parts and/or labor for an approved warranty claim must be submitted no later than 30 days after initial warranty claim was filed. All claims must be made out and submitted to Promar. All warranty claims are pending inspection of alleged defects in parts and/or workmanship. If any person and/or installer discard defective parts before Promar inspection, no warranty claim shall be honored. Unauthorized repairs will not be recognized or honored as a legitimate warranty claim. Any warranty monies due to installing dealer will not be discounted from any future sale. Customer irrevocably agrees to exclusive personal jurisdiction in the County of Passaic, State of New Jersey with respect to all claims against Promar pertaining to the sale of its product(s) or its warranty.

Transfer of Warranty:

Any request for warranty transfer must be done so in writing through Promar's Customer Service Department. Transfer of warranty can be done for vehicles 12 months in service or less and at the time of vehicle sale. A fee of $250.00 will be incurred for transfer of warranty.

WARRANTY

Cars and Light Duty Trucks:

3 Years - Unlimited mileage warranty includes any long block engine installed in any automobile or light duty truck up to and including ¾ ton, NOT commercially registered and NOT used for business purposes.

3 Years - 75,000 miles warranty includes long blocks installed in vehicles up to and including one (1) ton commercially registered or used for business, as well as privately owned one (1) ton vehicles.

\* Exclusions: Ambulance, Off Highway Use, Package Delivery, Police, Taxi, Limousine, Tow Truck or any vehicle over one(1)ton.

18 Months or 75,000 miles warranty includes any vehicle over one (1) ton, industrial, Box Trucks, Dual Rear Wheels, Service Bodies and non-automotive use.

Marine Engines:

24 months - Unlimited Hours Cylinder Heads: 6 months - Unlimited Mileage

Short Blocks:

6 months 6,000 Miles

PERFORMANCE ENGINE WARRANTIES

HO, Stroker & Marine Performance:

One Year Unlimited mileage/hour warranty covers original engine only, no labor for removal or replacement of engine. Covers manufacturer & parts defect only, to be determined by Promar inspection. If deemed to be non manufacturing fault, a fair assessment of remanufacture cost will be provided. If customer denies offer to rebuild all parts will be returned to customer.

Street Strip, Racing Series & Short Blocks:

NO Warranty due to the nature of use they are intended for.

Promar reserves the right to change vendors or part specifications without prior notification. All HP and TQ ratings are achieved on a Superflow Dyno in a controlled environment and tuned for maximum performance output. Actual HP in vehicle can vary due to tuning and bolt on items utilized by vehicle owner. Promar assumes no liability on horsepower output in vehicle.

Promar Engine's mission statement is to deliver quality, guarantee customer service, and remain committed to standards of excellence, ensuring a great product at a fair price.

When our company opened on October 1st 1993, our mission statement became a way of life for us. Our passion for performance enabled the company to offer a nationwide 3 year unlimited mileage warranty unheard of in the industry. Imitation is the sincerest form of flattery, so when some companies followed suit, we knew we had set a benchmark for excellence and customer service. By 1994 Promar Engines had grown to 72 employees. That same year New Jersey Business News Magazine named Promar Engines one of its top 25 fastest growing companies in New Jersey.

The PERA has awarded Promar Engines "Engine Rebuilder of the Year 2003". We take great pride in participating with organizations such as: The BBB, AERA, PERA, AAIA, AJE, AJA and APRA.

Here at Promar Engines we continue to reach new levels of customer service while offering consumers a wide range of services:

- » Remanufactured Engines

- » Cylinder Heads

- » Crankshafts

- » Diesel Engines

- » Marine Engines

- » State-Of-The-Art Machine Shop

- » Classic Automotive Engine Restoration

- » Performance Engines

We know that in this industry consumers have many choices. We want the opportunity to prove to you our commitment to excellence. Once you have chosen Promar Engines for your automotive needs, you will become our greatest testimonial.

Warranty: 3 Year

Returns Accepted: Yes

Item must be returned within: 30 calendar days

Return shipping will be paid by: BUYER